GAS DEHYDRATION

GAS DEHYDRATION

Natural gas normally contains a large amount of dissolved water and at the various processing stages of separation and compression after cooling, it is typically water saturated. In effect this means that any subsequent cooling will result in water condensing in the piping and downstream equipment which can create corrosion and hydrate problems which are potentially very expensive issues to resolve.

In most cases it is not practical to cool the gas temperature below pipeline operating temperatures or injection temperatures and as such the formation of free water must be prevent by removing some of the water from the gas to ensure that the water dew point or hydrate formation temperature is not operationally achieved.

The most popular gas dehydration technologies utilise aqueous solutions and typically follow gas treating and/or gas compression. Techniques for dehydrating natural gas include:

- Absorption using liquid glycol desiccants

- Adsorption using solid desiccants

- Inhibition by injection of hydrate point depressants

- Dehydration by expansion refrigeration (Low Temperature Separation)

Capital and Operating cost economics usually favour glycol dehydration over other processes where this process will meet the dehydration specification required. Tri-ethylene Glycol (TEG) is the most widely used glycol because of lower vapour losses combined with a greater dewpoint suppression. Solid desiccant processes such as molecular sieves can produce outlet water content as low as 1 ppm and as a result they are widely used for feed streams to cryogenic processing systems where water dewpoint specifications are very stringent.

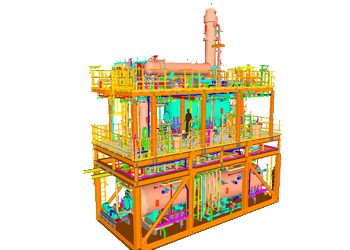

All dehydration processes have advantages for specific applications but also have disadvantages and potential issues. With over 50 years of experience in the design, supply and operation of Process Equipment Fraser Uniquip is able to provide optimised Dehydration solutions for specific applications.